Undergraduate Projects

Research Projects

2024-2025

Research Title:

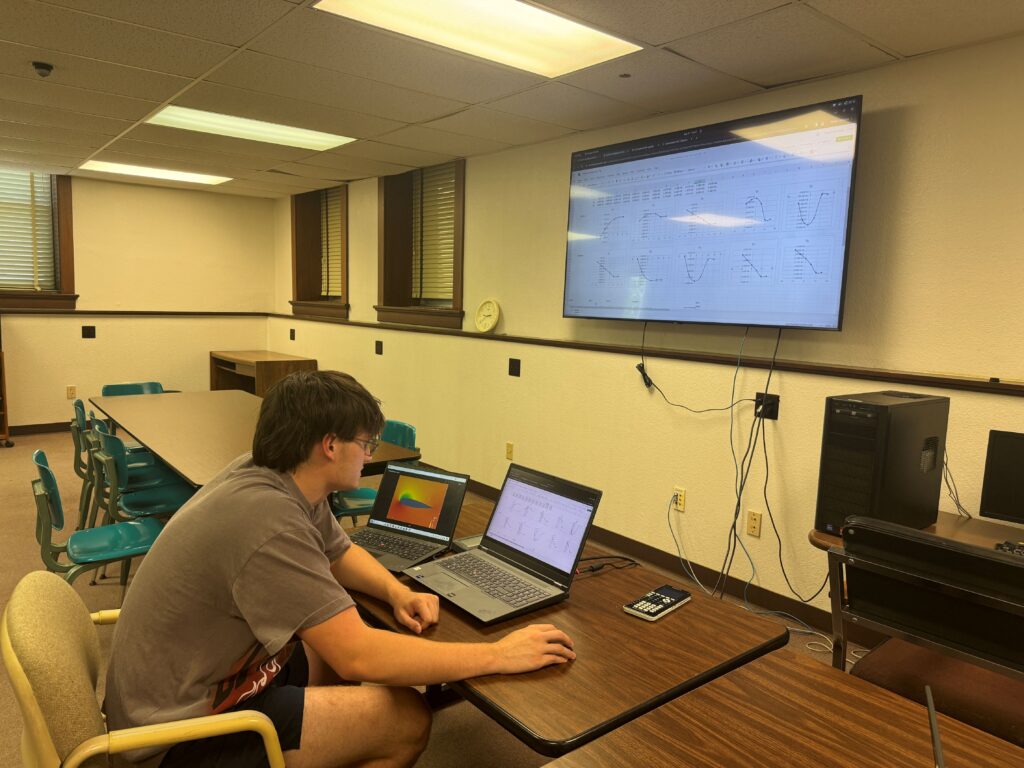

LIDAR-based 3D Spherical Harmonics with Information Fusion for Target Tracking (SHIFT) Filter for Space Domain Awareness and On-Orbit Servicing

Research Title:

Effect of carbon monoxide-entrapping materials on the prevention of intra-abdominal adhesions

Research Title:

DNA Testing Microbes From Wind Cave National Park, SD

Research Title:

Modulation of Thermal Gradients in Lithium-Ion Batteries

Research Title:

Computational External Flow Analysis and Validation Across Complex Aerospace Models

Research Title:

Optimizing Airspace Safety and Efficiency: Developing Predictive Algorithms for Seamless Integration of Unmanned and Manned Aircraft

Research Title:

Determining the mechanism of action of filociclovir against adenovirus and cytomegalovirus

Research Title:

The Effect of Motivation on Attentional Breadth

2023-2024

Research Title:

Identification of Microorganisms from the Depths of Wind Cave

Research Title:

Analysis of Double-Strand Break Repair Pathway Genes in Human Cancer Cell Lines

Research Title:

MISSFIT – Artificial Gravity Model for Interplanetary Space Travel

Research Title:

Analysis of Increasing DNA Damage on Levels of DNA Ligase IV Found in Cancer Cells

Research Title:

Using GIS to evaluate the habitat isolation among pollinator Conservation Research Program habitat

Research Title:

Entrance to Entrance: A Hunt for Astrobiological Analog Sites at Wind Cave

Research Title:

The Spectroscopic Characterization of Crystals and Waters at Wind Cave National Park as an Analog for Space

Research Title:

Verifying Post-Merger Stellar Evolutionary Processes

Research Title:

Implementation of a 10-meter Radius Centrifuge Model into a Simulator of the Human Cardiovascular System

Research Title:

Decoding Destabilization: Investigating the Mechanisms by Which Disruption of the RAD51:RAD51 Interface Affects RAD51 Nucleoprotein Filament Integrity and Function

Research Title:

Computational and Experimental Aerodynamic Analysis of Future Conceptual Commercial Aircraft Designs

Research Title:

Biotronics: Bio-Ion Gated Transistors

Research Title:

Near-Infrared Spectral Analysis of TYC 2597-735-1

Research Title:

MISSFIT – Artificial Gravity Model for Interplanetary Space Travel

Research Title:

Novel Applications of Hyperpolarized 129Xe Magnetic Resonance Imaging

Research Title:

Novel Matrices for Gas Entrapping Materials to Optimize Dissolution Kinetics and Delivery

Research Title:

Identification of Microorganisms from the Depths of Wind Cave

2022-2023

Research Title:

FACTS- Floating Attitude Control Test System

Research Title:

Identification of Microorganisms from the Depths of Wind Cave

Research Title:

Analysis of Double-Strand Break Repair Pathway Genes in Human Cancer Cell Lines

Research Title:

Properties of Mars Induced Magnetic Fields as Compared to Venus

Research Title:

Curing Nanocellulose for Extraterrestrial Applications

Research Title:

Analysis of Increasing DNA Damage on Levels of DNA Ligase IV Found in Cancer Cells

Research Title:

Multi Loop Control of Complex Autonomous Systems

Research Title:

Laser-Induced Graphene Ion-Selective Electrodes with Electrochemically Deposited Platinum Nanoparticles

Research Title:

Beam Me Up, Scotty! New Algorithms for Characterizing the Beams of Next-Generation CMB Experiments

Research Title:

Development of Remote-Controlled Compound MP Nanoparticles for Space Exploration

Research Title:

The Spectroscopic Characterization of Crystals and Waters at Wind Cave National Park as an Analog for Space

Research Title:

Working Towards Developing Fluxgate Magnetometers to be Used in Constellation Missions

Research Title:

Kinematic Shape Sensing of Two-Dimensional Plates in Bending

Research Title:

Adjustable X-ray Optics: A New Technology for High Energy Astrophysics

Research Title:

Computational and Experimental Aerodynamic Analysis of Future Conceptual Commercial Aircraft Designs

Research Title:

Near-Infrared Spectral Analysis of TYC 2597-735-1

Research Title:

Exploring Microbial Composition of Moonmilk in Wind Cave National Park

Research Title:

Novel Applications of Hyperpolarized 129Xe Magnetic Resonance Imaging

Research Title:

Novel Matrices for Gas Entrapping Materials to Optimize Dissolution Kinetics and Delivery

Research Title: