Accomplishments:

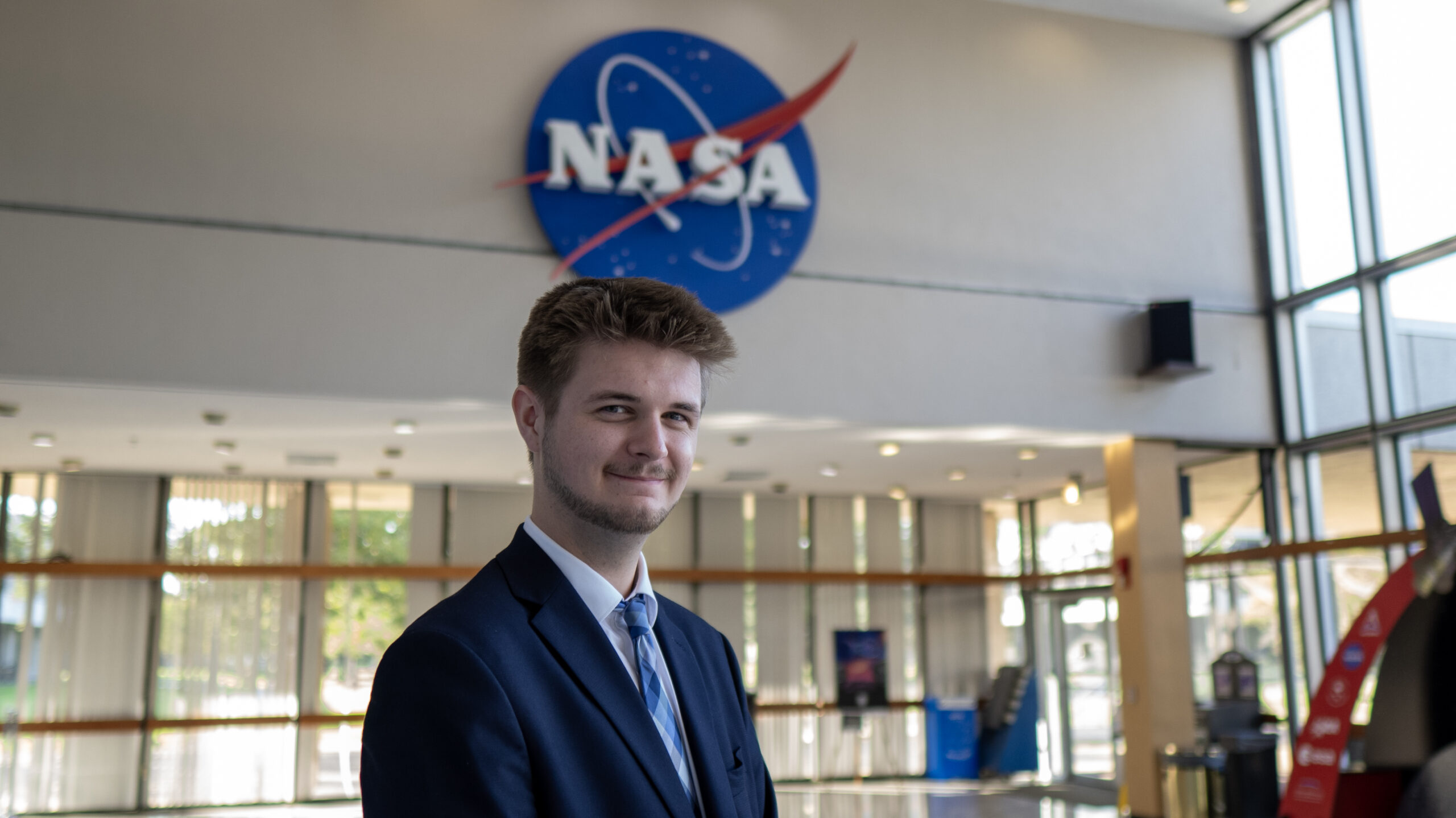

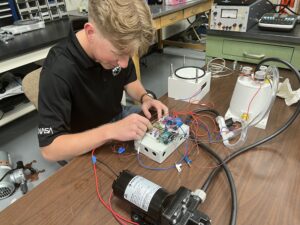

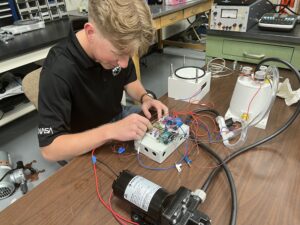

I developed new Isotonic mode firmware for the PKD (knee dynamometer), enabling astronaut strength training and rehabilitation at torques up to 240 ft-lb. I also contributed to ARC-ANGEL, a wearable system simulating lunar and Martian gravity, by building software and middleware for ODrive motor controllers, supporting the successful Test Readiness Review (TRR) and prototype deployment. Additionally, I assisted in the mechanical design of the UPRITE rack, a proprioception-training device, focusing on safe shell integration for astronaut use. I collaborate daily in a team of four interns and six mentors, integrating hardware, software, and firmware solutions across projects. Beyond project work, I engage with over 130 interns through the PIPE/SCuM professional groups, where I help organize events and participate in intern rocketry.

Mid-term Goals:

I plan to continue advancing the ARC-ANGEL system, improving performance and reliability of the ODrive control software gui, and supporting upcoming testing in NASA’s ARGOS offload facility. I also hope to refine the isotonic mode firmware for the PKD to further enhance astronaut training capabilities and to contribute to system-level integration across the hardware and software teams.

Impact:

This internship has been one of the most amazing experiences of my life. I’ve learned so much from incredibly talented mentors and peers. The intern community, both professionally and socially, has been inspiring and supportive, and I’ve built connections that I truly value. This experience has strengthened my passion for STEM and for NASA’s mission!I hope everyone has the opportunity to work in an environment like this someday, whether in STEM or Non-STEM, because it’s been wonderful.

Describe what you did during your internship:

Describe what you did during your internship:

Describe what you did during your internship:

Describe what you did during your internship: