Describe what you did during your internship:

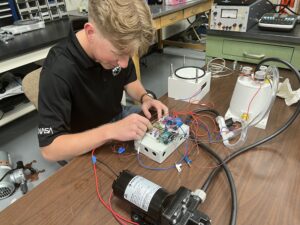

During this internship I participated in many fashions from my own project work to additional opportunities given to interns. For project work, my day-to-day included CAD modeling in CREO, using the MSFC Makerspace to 3d print and test parts, soldering circuit designs on protoboards, programming an Arduino UNO with the Arduino IDE, etc. Additional to PRIME, I spent plenty of time working on particle characterization which included running morphology as well as particle size distribution on AM powders and various regolith simulants. I also had the opportunity to take optical measurements on materials intended for flight under the Materials on International Space Station Experiment (MISSE) as well as on the passive side of Boeing’s Gateway docking station. There were also several tour opportunities such as to see Artemis hardware, the ISS Payload Ops Center & Lab Training Complex, and the National Center for Advanced Manufacturing (NCAM).

Did you achieve your goals?

During this internship, all goals and objectives put in place were not just met but exceeded. Over the course of the 16-week session, a complete overhaul of the system was completed. Ultrasonic transducers were successfully reverse engineered from an off the shelf ultrasonic cleaning unit and integrated into PRIME. Additionally, structural design changes were made in order to ensure a watertight system and a circuit capable of automatic operation was designed and soldered utilizing a protoboard and Arduino Uno. At the conclusion of the rapid prototyping process, a functional ground prototype was assembled. This ground prototype was then used to give a successful demo, drawing heavy interest in the future of PRIME. Following this demo, the ground prototype was put through initial testing which resulted in successful cleaning of contaminants during each test run. With this prototype verifying proof of concept and jumping the technology readiness level (TRL) of the ground version of PRIME, efforts were commenced to make progress towards a flight capable capsule. This involved collaboration the lead Glovebox Integration engineer at MSFC as the end goal of PRIME is to be launched to the International Space Station (ISS) for extensive microgravity testing as a Microgravity Science Glovebox (MSG) experiment. Towards the end of this 16-week session, a paper was written on the current status and design of PRIME as well as future work for the flight model. This paper will be utilized by future PRIME manpower as project guidance. Beyond this, a poster was produced to be displayed inside building 4711 at MSFC.

Describe positive lessons learned:

One of the biggest lessons I learned during this session was how to handle the difference between life in academia and life in industry. There was an initial learning curve of not going home and spending the entire evening diving deeper into my work. A major item for me was beating imposter syndrome, I was intimidated by the idea of coming to MSFC and had my own doubts. This internship showed me what I can do and has boosted my confidence as a student and engineer.

Describe negative lessons learned:

My one major takeaway as something to adjust to is implementing patience. Many situations have occurred where processes with NASA take longer then desired and caused unwanted downtime.

What was the impact of this internship?

This internship has opened the door to vast opportunities within NASA. Getting a taste of what working for NASA is like has inspired me to stay on this path and come back for an internship this summer, along with making my way to working for NASA full-time following graduation.